- Home

- Zinc Alloy

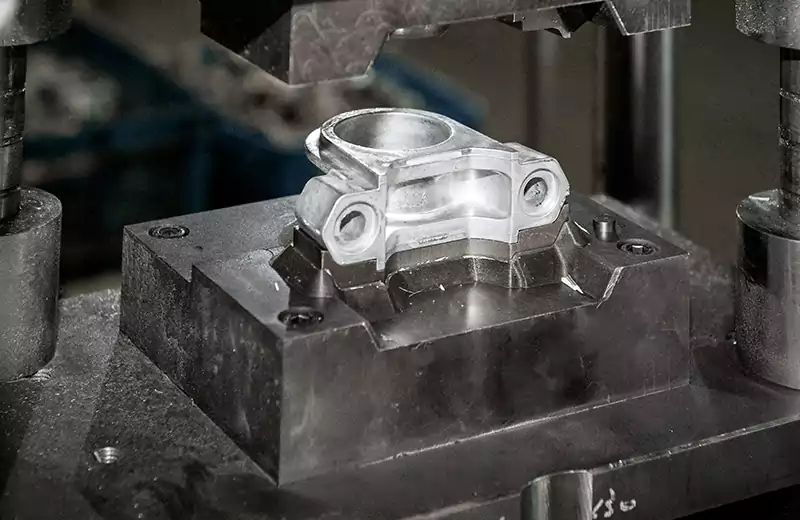

Zinc Alloy Casting Designed for You

TLP Casting is a certified custom zinc die casting manufacturer with more than 20 years of experience and service to different brands, including big and small scale businesses. With solid knowledge and understanding of all zinc alloy casting processing techniques, we offer outstanding services that help in achieving your project. Some of them are the provision of in-house tool design, construction, repairs, and modifications.

We stand out from other manufacturers on the market as we specifically offer you high-quality services within a short time and at a low price.

Why Choose Zinc Alloy for Die Casting Parts?

Zinc alloy is very unique, which is why it’s desirable for making parts that are used in many industries, including automotive and electronics. This material is extremely strong and rigid, yet through our unique die casting process is formable into parts with thin walls and intricate designs.

Also, zinc is a low-cost material that has good electrical and thermal conductivity, resistant to corrosion, and fully recyclable. When zinc is die cast, it turns to a monolithic part with great strength and durability that can’t be compromised with welds, bolts, or seams.

How to Choose Your Zinc Alloy Grade

| Alloy | Common Usage |

|---|---|

| Zamak 3 (Zinc Alloy 3) | This is arguably the most commonly used zinc die casting material. It possesses great properties, such as outstanding castability, durable dimensional stability, and ease of plating, painting and chromate treating. |

| Zamak 5 (Zinc Alloy 5) | It contains 1% of copper, contributing to its ability to produce castings that are stronger and harder than Zamak 3. This alloy has excellent castability and is simple to plate and finish. |

| Zamak 7 (Zinc Alloy 7) | This alloy has less magnesium content than Zamak 3, hence its increase in fluidity. It’s the best option for parts with thin walls, especially when a food surface finish is needed. |

| Zamak 2 | This is the strongest and hardest Zamak metal material as it has 3% of copper content, which is higher than that of other materials. |

| ZA-8 (Zinc Aluminum Alloy) | It’s similar to Zamak 2 in strength, creep, and hardness as it contains about 8.4% aluminum. This alloy is very easy to plate and finish, and is widely used for decorative components. |

Zinc Alloy Casting Portfolio

Request A Proposal

Make an appointment to visit factory online. Let our estimating and engineer team assess your project. Receive a proposal and free consultation.