- Home

- Success Stories

Success Stories

TLP Casting tackles metal casting challenges with ease. Explore our most recent projects to see it for yourself.

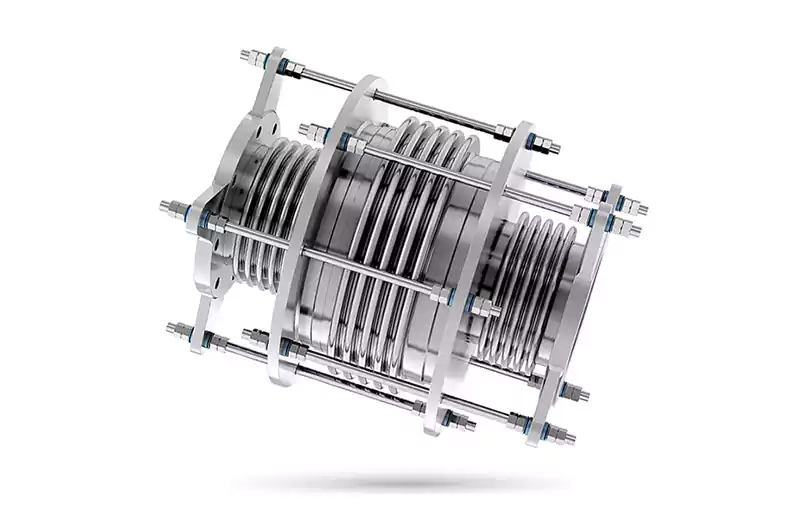

Transfer lines for Petrochemicals

Context:

A leading international German company specializes in the safe connection and transfer of petrochemicals and other sensitive liquids. The company has both a design and development teams that often revise each other’s drawing to discuss and ensure absolute success. Since 1923, their hoses, couplings, fittings, expansion joints, and nozzles have been setting the standard, which in turn enable them to offer quality and durable products.

Challenge:

Customers have their own mature procurement chain and are more demanding in terms of cost. They are very sensitive to the price slated for the design, development, and production stages. Also, their product quality requirements are very strict.

In terms of country challenges, Germany has some filing requirements for minerals, such as RMI’s CMT and CMRT, processes that require precise reference data.

Result:

A one-on-one discussion was set up with the company to confirm these problems and also make inquiries about some other information relating to the success of this project. Afterward, the challenges were digested by us making new product development. We sent it to the client and it was approved. Details and documents to be also supplied include the COO, material certification, size report, etc.

Client Says:

“Looks very good. Please keep us informed if there is any change in the delivery date of the 100 samples. We are looking forward to receiving the documents for the air freight.”

Heavy Duty Umbrella Base

Context:

This is for an Australian customer who deals with heavy duty support base products for parasols mainly used on beaches, pools, and outdoor decks. The products are sold worldwide through offline distributors and amazon.com. For the manufacturing, the customer gives a simple design concept and usage, while the technical department makes detailed drawings according to the requirements.

Challenge:

The customer chose to use carbon steel because other metal alloys are expensive and heavy, which increases the weight of the products. However, carbon steel is easy to rust and the product is usually used outdoors, meaning that they will begin to rust when they come in contact with wind, sun, and rain. If sprayed, it will only take a matter of time before it begins to rust again.

Result:

After many experiments and repeated salt spray tests, we finally chose to black electrophoresis first then spray, after which we will use black electrophoresis coating to meet the rust prevention requirements at the unpainted area. This will effectively stop the rusting problem and the cost will still be within the customer’s budget.

Client Says:

After up to a month of outdoor testing, the client said: “The rust issue has been solved. Thank you for all the help.”

Request A Proposal

Make an appointment to visit factory online.Let our estimating and engineer team assess your project.Receive a proposal and free consultation.