Effortlessly Investment Casting & Die Casting Manufacturer

Create 3D interactive prototypes and casting samples before making a final decision — upload your 2D/3D file to see instant pricing, lead time, and manufacturing feedback.

Our Services

Explore Our Lines of Precision Custom Metal Casting

One of the oldest known metal forming techniques that’s based on lost-wax casting. TLP Casting majorly uses two types of materials of investment casting, which are stainless steel and carbon steel. Metal mold and parts manufactured through this process are very versatile, resistant to heat, and have high dimensional accuracy.

Recommended Material

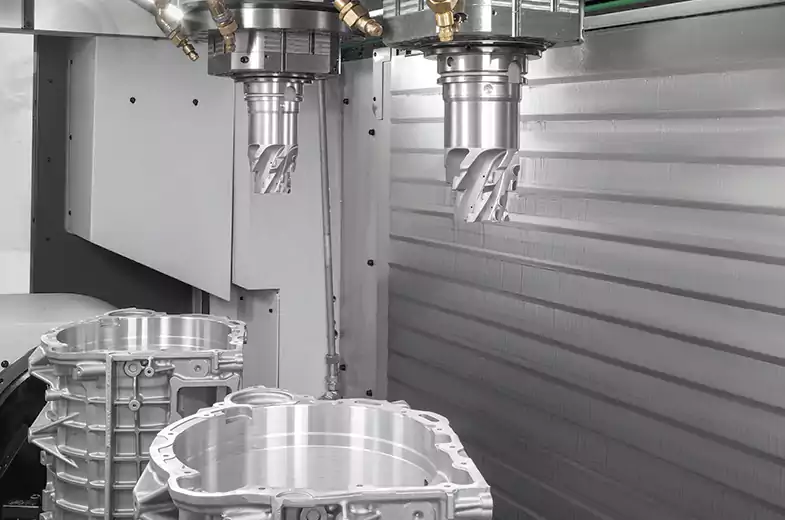

This is a metal casting procedure that’s characterized by injecting molten metal under high pressure into a mold cavity. With our great technical expertise in two major die casting materials (aluminum and zinc), TLP Casting casts extremely intricate parts with excellent surface finish in high volumes.

Recommended Material

Full-Service Casting Capabilities

What Makes Us Different

Engineered to be Nimble

Injection Tooling

Rapid Prototype Castings

Hold Tight Tolerances

Customized Packaging

Industry-specific Experience

TLP Casting is Dedicated to Exceeding Expectations

Over the years, TLP Casting has partnered with over 50 super brands, offering assistance to all their metal casting needs. With great specialty in turning drawings, designs, and concepts into solid products, we conform strictly to the industry regulatory standards with the ISO 9001 and ISO/TS16949 certificates to prove our capability.

Having three workshops (investment casting workshop, die casting workshop, R&D packaging workshop), all manufacturing processes are carried out in-house. This helps to ensure conformance with customers’ specifications and quality standards.

Casting by Industry

Medical

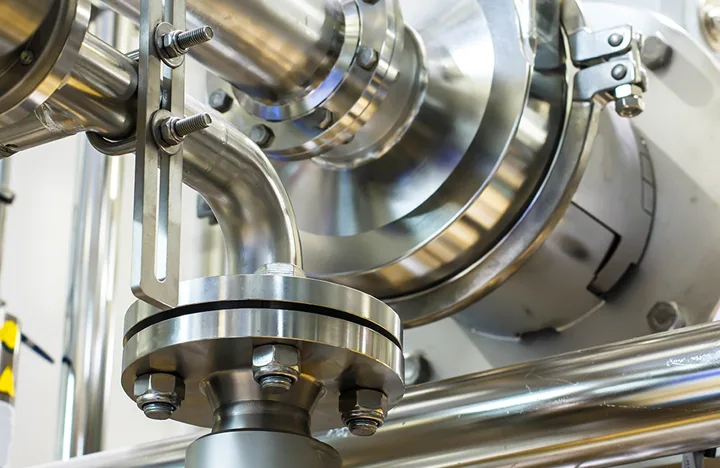

Pumps & Valves

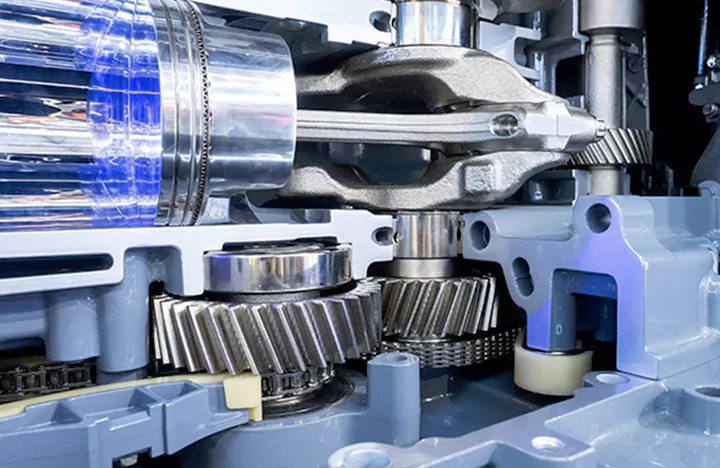

Automotive

Aerospace

Agriculture

Construction

Power Transmission

Manufacturing

Cast parts in manufacturing are commonly used in brackets, connectors, gear drives, and fasteners. Connectors secure and link components to ensure system stability and safety, while gears facilitate rotation and power transmission.

Oil & Gas

Case Studies

Delivering Total Casting Success with Real Results

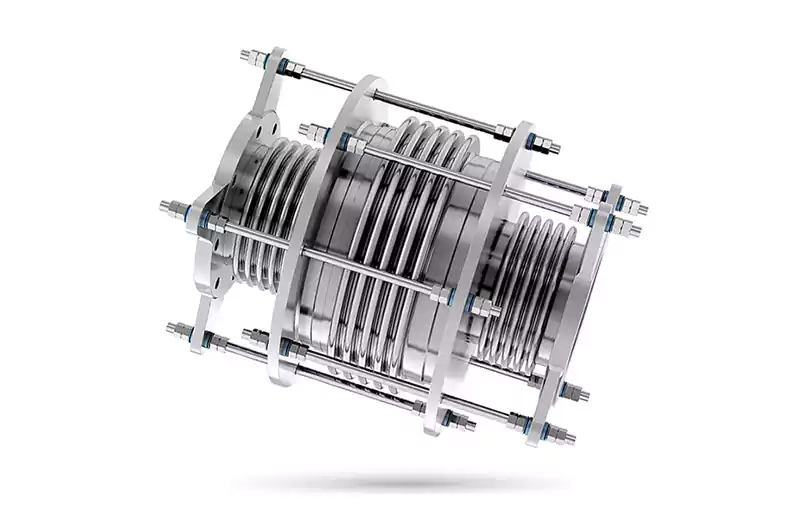

Transfer lines for Petrochemicals

A leading international German company specializes in the safe connection and transfer of petrochemicals and other sensitive liquids. Since 1923, their hoses, couplings, fittings, expansion joints, and nozzles have been setting the standard, which in turn enable them to offer quality and durable products.

Heavy Duty Umbrella Base

This is for an Australian customer who deals with heavy duty support base products for parasols mainly used on beaches, pools, and outdoor decks. The products are sold worldwide through offline distributors and amazon.com.

Commitment to Quality

And Go Green Initiative

TLP Casting prioritizes corporate social responsibility as it’s in our mission to reduce the amount of CO2 released into the environment from our manufacturing processes.

With the aim to promote environmental sustainability, we implement the “Go Green Initiative” that ensures that all stages of production are strictly monitored to make sure that the outside environment is not polluted.

Request A Proposal

Make an appointment to visit factory online.Let our estimating and engineer team assess your project.Receive a proposal and free consultation.