- Home

- Materials

Materials & Options

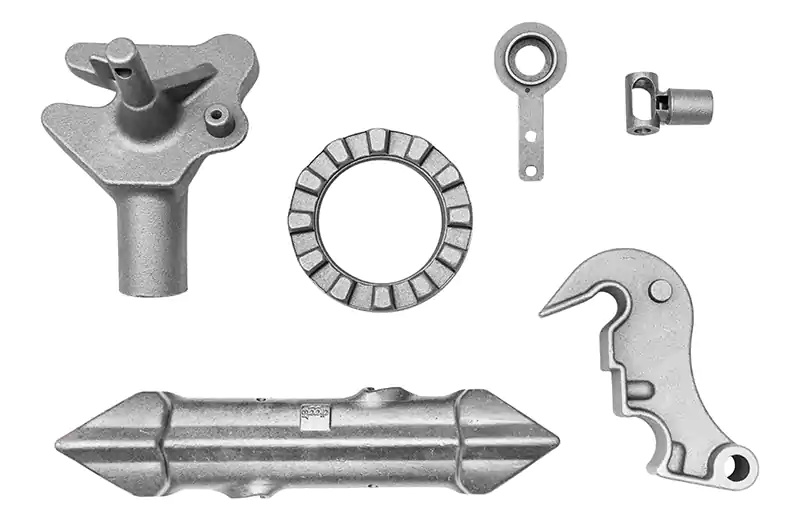

TLP Casting is a certified investment casting and die casting manufacturer with an extensive capability in using different types of materials that offer several benefits like high strength, resistance to temperature and corrosion, as well as reduced cost.

With 20+ years of experience in working with a wide range of industries, including medical, pumps & valves, automotive, aerospace, agriculture, construction, power transmission, military & defense, and oil & gas, we’ve built a reputation of providing high-quality castings.

Stainless Steel Casting

Using various grades of stainless steel alloy (such as 304, 304L/316L, 316, 410 & $16, and 17-4), you will be provided with strong and tough casted parts that perform optimally and last long. Custom finish operations like powder coating, painting, and electropolishing can also be performed to improve the aesthetics and durability of the castings.

Carbon Steel Casting

Carbon steel is one of the strongest and toughest metal alloys for making all kinds of parts, especially components that are frequently exposed to harsh conditions like roughneck equipment for oil & gas and pumps & valves operations. It contains numerous intrinsic properties, such as wear resistance, high strength with increased toughness and hardenability.

Aluminium Casting

As a verified aluminum die casting manufacturer, we provide design, engineering, and tool making services that guarantees the success of your project. Aluminum has many properties, which makes it suitable for several industries. Despite its lightweight design, it has high strength, fully recyclable, and offers more surface finishing options.

Zinc Alloy Casting

This material is very hard and tough, yet formable into parts with complex geometry and thin walls. In conjunction with the several benefits that come with zinc alloy casting, you will be provided with in-house tool design, construction, quick samples, repairs, and modifications at a competitive price.

Case Study

Transfer lines for Petrochemicals

A leading international German company specializes in the safe connection and transfer of petrochemicals and other sensitive liquids. Since 1923, their hoses, couplings, fittings, expansion joints, and nozzles have been setting the standard, which in turn enable them to offer quality and durable products.

Looks very good. Please keep us informed if there is any change in the delivery date of the 100 samples. We are looking forward to receiving the documents for the air freight.

Zareefa Arije, ELAFLEX

Request A Proposal

Make an appointment to visit factory online.Let our estimating and engineer team assess your project.Receive a proposal and free consultation.