- Home

- Carbon Steel

Carbon Steel Casting Designed for You

TLP Casting is a one-stop carbon steel casting manufacturer that’s certified by ISO 9001-2015 for the production of components that perform effectively and last long. With the specialty of our engineers and use of advanced machinery, such as the Wenzel 3-Axis Dimensional Measuring Machine for ensuring appropriate dimensions and our Oxford Spectrometer for checking the chemical composition, you will get metal parts with tight tolerances and complex designs. Our capabilities also extend to making rapid samples and offering secondary operation services.

Why Choose Carbon Steel for Investment Cast Parts?

Carbon steel is the main element in this steel alloy, which is why it’s extremely hard and strong. Carbon steel is the best option for parts that require resistance to wear and corrosion, as well as high strength and toughness. It is versatile and can be used across many applications.

Aside from the benefits above, you’ll be offered secondary operation services, including DFM, CNC machining, and custom finishes, which makes your products more attractive, functional, and durable.

How to Choose Your Carbon Steel Grade

| Alloy | Common Usage |

|---|---|

| 1018 & AISI 1020 | These are the softest of the three most common carbon steel grades, as they will bend rather than break under high pressure. They are often used to make handles, cranks, braces, and some other components used for construction, machine tool, and automotive applications. |

| 4130, SAE 4140 & 4140 MIL-S | These sets of carbon steel have high strength and are used for making parts that mustn’t deform. They are often used to cast firearm components, ratchets, and some other components used in the petrochemical and automotive industry. |

| SAE 8620 | Also known for its extreme resistance to corrosion, it’s used for making parts like housings, gears, plates, and other components that are used in the marine, automotive, petrochemical, and food & dairy industries. |

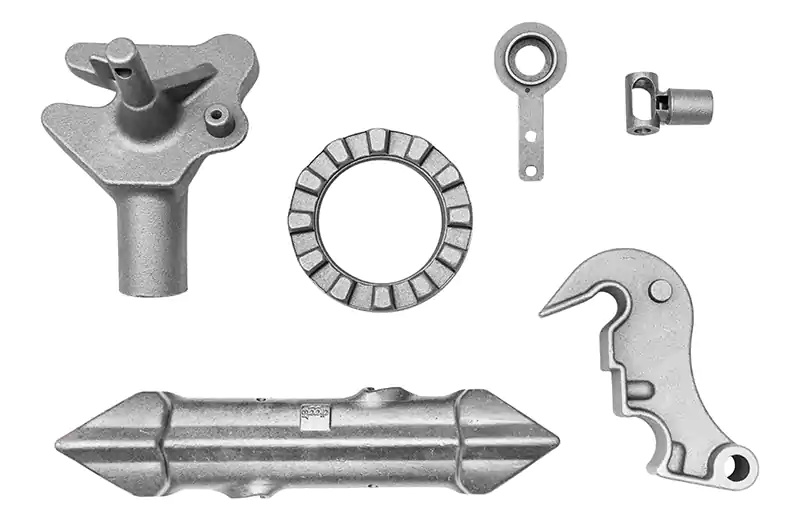

Carbon Steel Casting Portfolio

Request A Proposal

Make an appointment to visit factory online. Let our estimating and engineer team assess your project. Receive a proposal and free consultation.