- Home

- Die Casting

High Volume Die Casting Designed for You

TLP Casting is a professional die casting manufacturer with over two decades of experience in the delivery of high-quality services on various parts that are used across several industries. With expertise in casting metal parts using aluminum and zinc, premium solutions are designed and developed uniquely for you at a cost-friendly price.

Why Choose TLP

Endless Options

Provided for you are hundreds of materials to choose from. Depending on your project, we try our best to satisfy all your demands as a combination of materials can be made.

Why Choose TLP

Easy to Use

Thanks to our 20+ years of experience in die casting, your designs, drawings, and concepts will be perfectly turned into solid parts. You are guaranteed the best services regardless of your budget constraint.

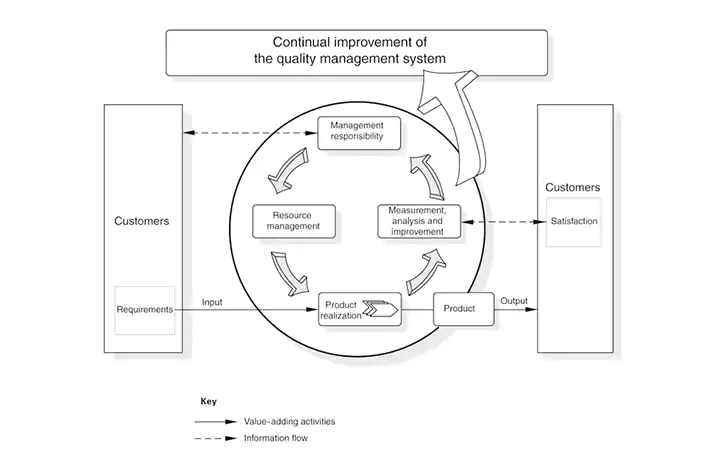

Quality & Certification

Castings are manufactured in the appropriate dimension with the tolerance ranging from +/-0.003 to 0.005 per inch. For the production of quality parts, we’ve received several certifications, including ISO 9001 and Quality Management System.

Our Die Casting Process

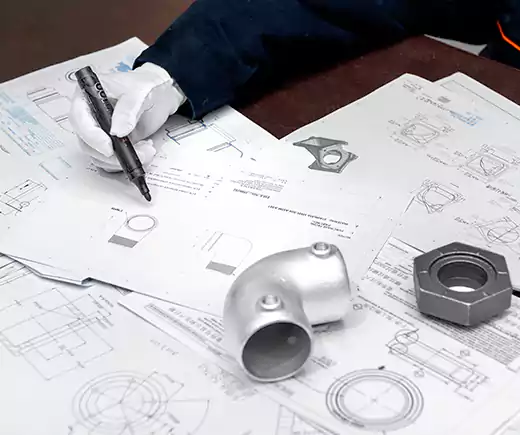

Manufacturing Analysis

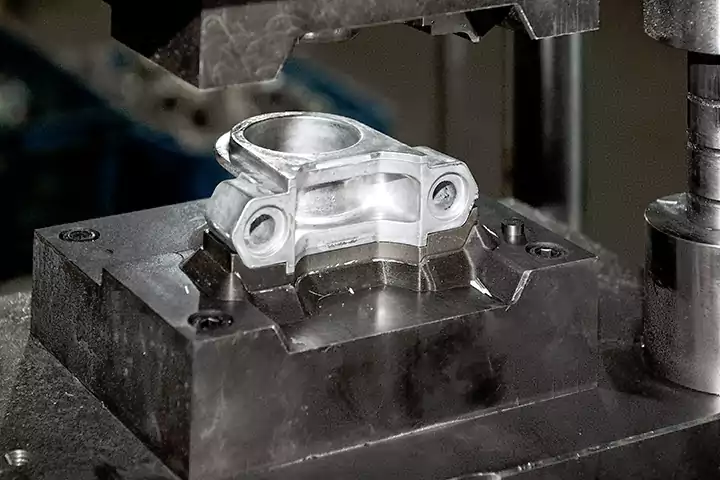

Create a Mold Tool

Injected Metal Assembly

CNC Machining

Surface Treatment

Trimming

Die Casting Quality Control

TS16949 Quality Management System

Disciplined Process Control

Superior Measuring and Monitoring

Continuous Improvement

Die Casting Service By Materials

Aluminum Die Casting

Possess numerous intrinsic properties, which makes it suitable for many industries. It’s lightweight, yet provides great strength, hardness, and rigidity. Among other die casting alloys, aluminum has the highest capacity in withstanding operating temperatures and offers more surface finishing options. Its other benefits are corrosion resistance, high thermal & electrical conductivity, and fully recyclable.

Zinc Die Casting

Zinc is a very strong, hard, and tough metal, yet can be formed into parts with thin walls and complex shapes. Also, it offers good electrical conductivity, high thermal conductivity, corrosion resistance, and is completely recyclable. It goes for a relatively low price.

Available Die Casting Finishes

Standard (As-Cast)

Bead Blasted

Powder Coating

Chemical Film

Plating

Custom Finishes

Applications of Die Casting

Having solid knowledge of die casting and use of technology, we effortlessly achieve our aim of helping customers make profit by saving their cost, solving technical issues, and delivering high-quality products & services. Our extensive capabilities range through making casted parts for several applications, like aerospace, automotive, pumps & valves, appliances, and lighting.

Request A Proposal

Make an appointment to visit factory online.Let our estimating and engineer team assess your project.Receive a proposal and free consultation.