- Home

- Capabilities

Our Capabilities

TLP Casting is a full service metal casting company that provides a full suite of casting parts used by several industries, such as medical, automotive, aerospace, agriculture, oil & gas, construction, and power transmission. Having a streamlined production process and capability to handle different metal materials, we help save your time and money.

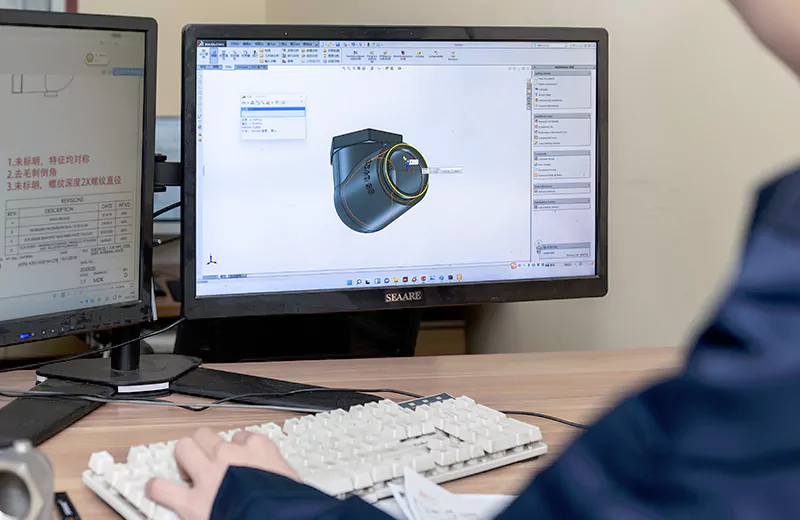

Design & Engineering For Manufacturing

With the expertise of our technical team, TLP helps enhance and improve your designs. In the event of any modification, you will be notified before moving to the metal casting process. And depending on your project, you can be assisted in choosing the best material (stainless steel, carbon steel, aluminum, or zinc alloy) and manufacturing process (investment casting or die casting) that’s most appropriate.

In-house Tool Making

All production processes are carried out in our well-equipped factory. With our skilled engineers and cutting-edge machinery, TLP can help you with your functional analysis and mold design. Also, we have Oxford Spectrometers that can analyze chemical components of metal alloys and Wenzel 3-Axis Dimensional Measuring Machine that’s used for checking the casting back to the 3D cad file.

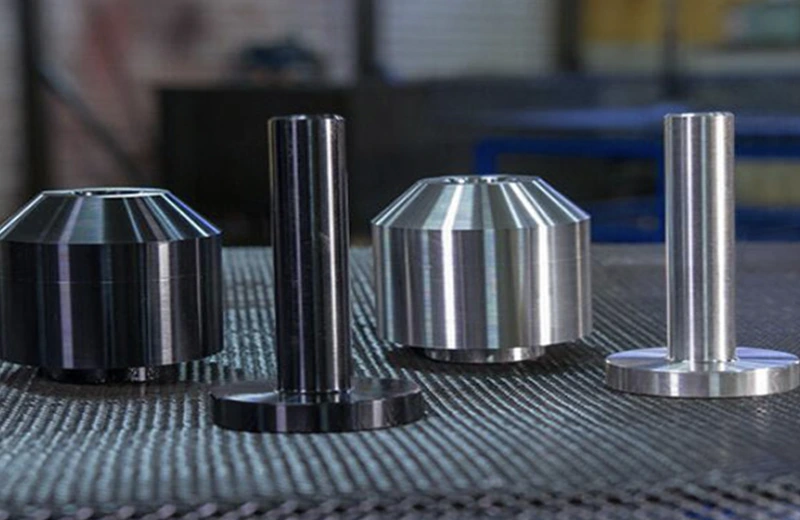

CNC Maching

TLP is experienced in the challenging machining of alloys, including simple, complex and custom designs, which is why we keep investing in the highest quality CNC machining equipment. We accept your technical drawings, carefully examine each blueprint requirement like the profile, surface finish, and tolerances. Afterward, our engineer and support teams get to work, ensuring that you get quality CNC machined parts on time.

Fully Finish Components

To ensure you use your metal cast parts for a long time while it maintains its beauty and functionality, TLP implements rich surface finishing options for investment casting and die casting applications. After production is completed, we smoothen, plate, and paint them to have rich surface finishing. All these are done in-house.

Non-destructive Testing

Partnering with us, you are guaranteed quality assurances that cements your reliability in the cast parts we produce. As an AS 9100 certified manufacturer, we support all standard non-destructive testing procedures. With an understanding that every part manufactured has an impact on the success of your applications, we take time to ensure that they do not falter at any point.

Custom Packaging For Protecting

Our capabilities extend to making custom packaging for protecting your engineered cast parts and equipment. Following your instruction, we can also design them to have your brand name and logo, which helps to build your business image. All these are done in our packaging lab at a competitive price.

Request A Proposal

Make an appointment to visit factory online. Let our estimating and engineer team assess your project. Receive a proposal and free consultation.